Solutions Built for the Future

Driving Innovation through Our Portfolio

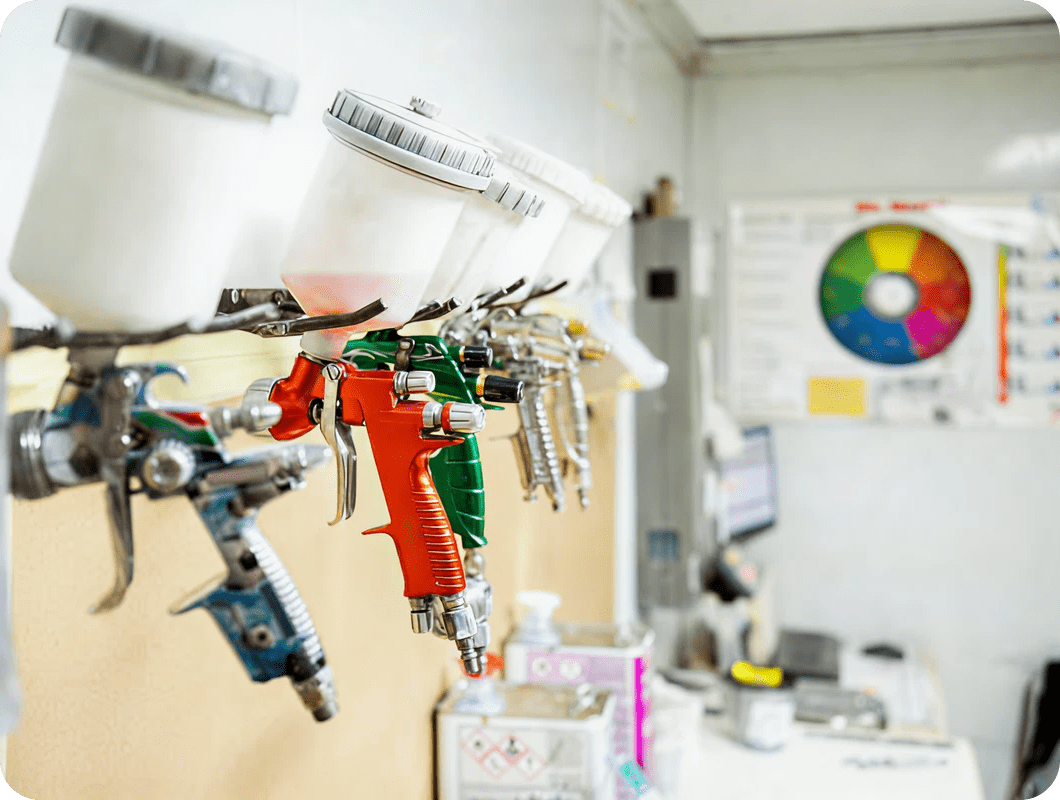

INDADD's advanced product portfolio is designed to address the most demanding industrial challenges. From performance-driven paint driers to versatile metallic stearates, our solutions empower industries like coatings, construction, and chemical processing with reliability, precision, and sustainability.

“Championing sustainable innovation in additives, we empower the paint industry and beyond to achieve a lasting global impact.”

Product Portfolio

Our product range is designed to fuel your success, offering performance-driven solutions for even the toughest industrial challenges.

Paint Driers

- Multi-metallic Solutions: Optimize drying times for solvent- and water-based alkyd resins while improving inventory management and minimizing dosage errors.

- Wide Range of Metals: We offer carboxylates with metals like cobalt, calcium, zirconium, zinc, and manganese, as well as niche options like potassium, lithium, and strontium.

- Flexible Concentrations : Customizable concentrations, including high concentrations developed with over-base technology.

Applications

- Solvent-based and water-based paint and ink driers.

- PVC foaming agents (kickers).

- Catalysts for unsaturated polyester resin and other chemical reactions.

Benefits

- Enhanced Efficiency: Accelerates drying times, improving production speed and efficiency.

- Reduced Material Usage: Optimizes the amount of raw materials needed, reducing costs.

- Minimized Errors: Decreases the risk of weighing errors during formulation.

- Improved Surface Quality: Helps prevent surface defects like wrinkles in paint films.

We adapt our products to meet specific customer needs for alkyd and water-based paints, polyester resins, and other applications.

Types of Paint Driers

These initiate surface drying quickly by catalyzing cross-linking in resins. For primary driers, we utilize octoates like cobalt, iron, manganese, cerium, and copper naphthenate. Cobalt octoate is widely used in the coating industry for surface drying, while iron octoate is effective at high temperatures. Manganese octoate is often combined with cobalt for enhanced performance, and cerium octoate excels in alkyd-based varnishes. Copper naphthenate is used as an anti-fouling agent, bactericide, and catalyst in ship bottom paints.

Ensure uniform drying throughout the entire coating layer, preventing wet film beneath the surface. In secondary driers, zirconium and strontium octoates are key players. Zirconium octoate is known for its efficiency and stability, while strontium octoate offers cost-effective auxiliary drying characteristics.

Enhance the effects of other driers without direct drying capabilities.

For auxiliary driers, calcium, zinc, and potassium octoates are commonly used. Calcium octoate enhances gloss and hardness, zinc octoate prevents wrinkling and offers mold resistance, and potassium octoate is used to reduce the “pinking” effect of cobalt.

These specialized formulations are designed to optimize the production process and performance of coatings.

PQMIX 100 and PQMIX WE streamline production and improve whiteness, PQMIX P3 enhances drying times for solvent-based resins, and PQ2002 improves color appearance and reduces costs on pigments and brighteners.

Tailored for water-based systems, these driers ensure efficient drying without compromising environmental standards, offering a sustainable solution for modern coatings.

Designed to meet regulatory requirements and environmental concerns, these driers offer effective drying without the use of cobalt, ensuring safety and compliance.

Product Portfolio

Our product range is designed to fuel your success, offering performance-driven solutions for even the toughest industrial challenges.

Types of Paint Driers

These initiate surface drying quickly by catalyzing cross-linking in resins. For primary driers, we utilize octoates like cobalt, iron, manganese, cerium, and copper naphthenate. Cobalt octoate is widely used in the coating industry for surface drying, while iron octoate is effective at high temperatures. Manganese octoate is often combined with cobalt for enhanced performance, and cerium octoate excels in alkyd-based varnishes. Copper naphthenate is used as an anti-fouling agent, bactericide, and catalyst in ship bottom paints.

Ensure uniform drying throughout the entire coating layer, preventing wet film beneath the surface. In secondary driers, zirconium and strontium octoates are key players. Zirconium octoate is known for its efficiency and stability, while strontium octoate offers cost-effective auxiliary drying characteristics.

Enhance the effects of other driers without direct drying capabilities.

For auxiliary driers, calcium, zinc, and potassium octoates are commonly used. Calcium octoate enhances gloss and hardness, zinc octoate prevents wrinkling and offers mold resistance, and potassium octoate is used to reduce the “pinking” effect of cobalt.

These specialized formulations are designed to optimize the production process and performance of coatings.

PQMIX 100 and PQMIX WE streamline production and improve whiteness, PQMIX P3 enhances drying times for solvent-based resins, and PQ2002 improves color appearance and reduces costs on pigments and brighteners.

Tailored for water-based systems, these driers ensure efficient drying without compromising environmental standards, offering a sustainable solution for modern coatings.

Designed to meet regulatory requirements and environmental concerns, these driers offer effective drying without the use of cobalt, ensuring safety and compliance.

Paint Driers

- Multi-metallic Solutions: Optimize drying times for solvent- and water-based alkyd resins while improving inventory management and minimizing dosage errors.

- Wide Range of Metals: We offer carboxylates with metals like cobalt, calcium, zirconium, zinc, and manganese, as well as niche options like potassium, lithium, and strontium.

- Flexible Concentrations: Customizable concentrations, including high concentrations developed with over-base technology.

Applications

- Solvent-based and water-based paint and ink driers.

- PVC foaming agents (kickers).

- Catalysts for unsaturated polyester resin and other chemical reactions.

Benefits

- Enhanced Efficiency: Accelerates drying times, improving production speed and efficiency.

- Reduced Material Usage: Optimizes the amount of raw materials needed, reducing costs.

- Minimized Errors: Decreases the risk of weighing errors during formulation.

- Improved Surface Quality: Helps prevent surface defects like wrinkles in paint films.

We adapt our products to meet specific customer needs for alkyd and water-based paints, polyester resins, and other applications.

Custom Solutions

We work closely with customers to craft bespoke additives that align perfectly with their operational requirements and goals. Every solution, whether for coatings or waterproofing, is designed with care and excellence.

Benefits:

- Enhanced Performance and Efficiency

- Reduced Costs and Material Usage

- Reliable, High-Quality Results

- Sustainable and Eco-Friendly Options

Download Our Products Brochure

Explore our comprehensive range of products in detail. Click the button below to download the brochure and discover how our solutions can meet your needs.

Excellence in Innovation, Quality, and Production

INDADD’s state-of-the-art JV manufacturing plant in Jubail Industrial City, Saudi Arabia, combines advanced technologies with responsible practices. We deliver solutions tailored to specific needs, balancing technological efficacy with environmental consciousness.

Explore our innovative range and join us in shaping industries responsibly.

At INDADD, innovation drives progress. Through partnerships with industry leaders like Producciones Químicas (PQ), we conduct collaborative research to create smarter solutions.

Our advanced laboratories, pilot plants, and application development labs support groundbreaking work, ensuring new formulations meet the highest technical and performance standards. By integrating real-time optimization technologies and continuous feedback loops, we stay ahead of industry demands.

Uncompromising quality is at the core of everything we do. Rigorous inspection protocols, from raw material validation to final product testing, ensure reliability. Advanced analytical tools, real-time monitoring, and statistical sampling enhance precision.

Through Total Quality Management (TQM), we empower employees to drive continuous improvement and actively incorporate customer feedback to refine our products. The Plan-Do-Check-Act (PDCA) Cycle helps us test and standardize changes efficiently.

We prioritize employee training in quality principles while leveraging technology like advanced analytics and automated systems for real-time monitoring and defect detection. Methods such as DMAIC (Define, Measure, Analyze, Improve, and Control) and Kaizen further enhance efficiency, supported by ISO-aligned systems to maintain global standards of excellence.

Efficiency drives every aspect of our operations, supported by key metrics to ensure continuous improvement and peak performance:

- Overall Equipment Effectiveness (OEE): Identifying opportunities for productivity and performance enhancements.

- First Pass Yield (FPY): Upholding quality standards by reducing the need for rework.

- Cycle Time: Streamlining processes to achieve faster production timelines.

- Scrap Rate: Reducing waste to improve material utilization and cost-effectiveness.

- Customer Satisfaction: Measuring success through your feedback and confidence in our solutions.

By focusing on these measurable outcomes, we aim to provide consistent, high-quality results that align with your goals.

Digital and automated solutions are critical to enhancing our efficiency, quality, and innovation. Through data analytics, we optimize production processes and implement predictive maintenance to reduce downtime. IoT sensors allow real-time monitoring of production parameters, ensuring consistent quality. We also streamline operations through IoT-enabled supply chain tracking for greater visibility.

Automated systems are at the center of our production process, enabling precise materials mixing, dispensing, and automated quality inspections. These advanced manufacturing technologies ensure consistency, reduce waste, and support rapid innovation in paint drier formulations. Together, these solutions contribute to operational excellence and support advancements in performance.

Sustainability shapes every aspect of our manufacturing philosophy, blending innovative material science with ethical responsibility. From creating cobalt-free and 2-EHA-free formulations to optimizing energy use, we aim to balance performance with environmental mindfulness. Advanced technologies for energy efficiency, water conservation, and waste reduction are central to our operations, helping us minimize resource consumption and environmental impact.

Metrics like carbon footprint, VOC emissions, and energy consumption guide our efforts, while sustainable sourcing ensures our raw materials align with eco-friendly principles. We also prioritize recycling and refined waste management processes to responsibly manage production byproducts.

Our drive for sustainability extends to fostering employee participation through environmental awareness programs, planting a collective sense of stewardship across the company. Certified under ISO 9001, 14001, and OHSAS 18001, we remain dedicated to safety, innovation, and paving a thoughtful path toward a greener future.

Request Your Tailored Additive Solution Today

Discover Our Success Stories

Curious about how our products make a difference? Visit our Testimonials Page to read inspiring stories from our customers. Learn how we've helped businesses across various industries achieve their goals with innovative solutions and exceptional service.